Brand design: the power to touch people's hearts and the art of shaping the soul of a company

What does a high-end first-class seat look like? For passengers, it may be more about comfort, while for railway operators, it is also necessary to consider economic benefits and other aspects... The power of industrial design integrates all these needs and makes a vague and broad concept eventually become a product with market value. On September 20, the 2024 World Industrial Design Conference opened in Yantai, Shandong. Many cutting-edge research results, including "China's high-speed rail high-end first-class seats for 450 kilometers per hour", were unveiled, showing the latest expressions of industrial design in the fields of marine engineering, rail transit, biomedicine, etc.

This is also the fifth time that Shandong has "joined hands" with the World Industrial Design Conference. "Industrial design is a process of solving problems." In the view of Li Chenglong, director of industrial design at Shandong Industrial Design Research Institute, new products and even a new industry can often "grow" from industrial design. Over the past five years, as the strength of industrial design has reached a new level, new momentum has been continuously injected into the development of Shandong's manufacturing industry. Corresponding to the theme of this year's conference, "Design·New Quality Productivity", "new" design driving "new" manufacturing has also become the most concentrated and vivid portrayal of Shandong's promotion of the deep integration of scientific and technological innovation and industrial innovation and the development of new quality productivity.

In the very "competitive" new energy vehicle field, "new" design is the most effective means to enhance the competitiveness of the industry.

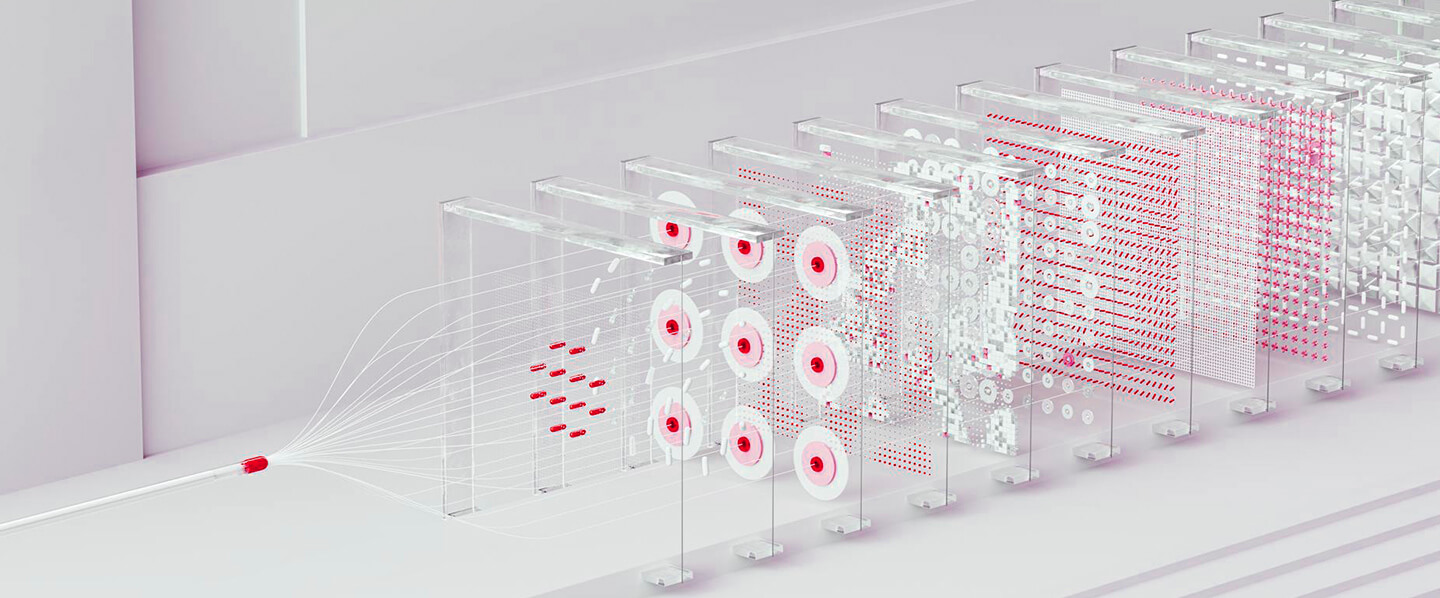

In the past, a production line with a cost of over 100 million yuan could only produce one car, while the main line of intelligent automotive welding developed by Maihe Robot Automation Co., Ltd. uses 64 robots to work together, which can meet the production of four platforms and eight models on the same line, and support the flexible expansion of subsequent models. It has now been successfully applied to many mainstream domestic car companies.

"Such an industrial design product landed in the production workshop, which is the integrated result of digital intelligence technologies such as automation, flexibility, and intelligence, but in fact, the design process of the production line itself is also inseparable from the empowerment of multiple new technologies." General Manager Zhang Kaixu introduced that in order to improve the first-time delivery qualification rate, a production line needed to be pre-integrated in its own factory first, and then the customer's car was brought to the production line for a run, and it took at least two months to install and disassemble. Now, with the use of offline simulation and virtual debugging technology, this design process is completed on the computer, and many problems can be discovered and solved in the early stage, thereby greatly improving the first-time delivery qualification rate after installation on the customer's site. "According to the car companies served, the previous first car body qualification rate was about 80%; and the first body qualification rate of this production line reached 93%, which is currently the industry-leading level." Zhang Kaixu said that from the past two years to build and operate a production line, it can now be completed in as fast as eight months. The time spent on the production line is shorter, which means that the market launch speed of car companies' products can be continuously accelerated, and China's new energy vehicles can further accelerate the new trend of international automobile production.

The rapid growth of the fresh food consumption market has made cold chain warehousing popular. Now many places are continuously improving the layout of cold chain facilities in the "first kilometer"; but compared with general warehousing, cold chain warehousing needs to operate in an environment of minus 25 degrees, and operators have to wear cotton jackets to drive forklifts. Using the power of "new" design, Linyi Lingong Intelligent Information Technology Co., Ltd. can make the warehousing environment quieter and more comfortable, and the auxiliary decision-making information provided is more scientific and timely.

"A cold chain warehouse with eight lanes, covering an area of 15,000 square meters and 18 meters in height, under traditional conditions, manual pick-up and delivery requires about 20 forklift operators and 4 warehouse managers to register goods; now with intelligent three-dimensional warehousing, with the help of laser forklifts and high-speed warehouse transfer RGV, all logistics porters can be saved, and two staff members at the entrance and exit can complete the storage and retrieval of goods using electronic equipment, which can better ensure the safety and quality of goods and greatly improve the efficiency of storage and retrieval operations." Listen to Su Yue, director of Lingong Zhike Intelligent Warehousing Research Institute, important principles in warehousing management such as "first in, first out" were difficult to fully realize by relying on manual management in the past. Intelligent warehousing systems that apply technologies such as automated logistics equipment integrated scheduling can ensure that the "prescribed actions" are completed 100%; more importantly, the digital twin warehousing system allows managers to have a pair of "perspective eyes" while sitting in the office, and change from relying on personal experience and subjective judgment in the past to making scientific decisions based on the system's analysis of information such as storage capacity rates in different cycles, so that supply and demand can be matched more efficiently.